The Role of a Color Proof

O nce a print job is on the press, changes are costly. The primary role of a color proof is to predict what a job will look like when printed. Using a color proof – and knowing what to look for in a proof – saves time and money by allowing changes to be made before a job goes on press. A proof serves as a communication and quality control tool at many steps in the production process. It is used within a production environment to monitor how a job is progressing. It is used with the customer to determine if color correction is necessary. It is used with the printer to check image quality and sere as a pressroom guide. A color proof often serves as a "contract" between the printer and the customer. This means the customer expects that the printed sheet will look like the proof. In the pressroom, the press operator makes adjustments to produce printed sheets that match the proof.

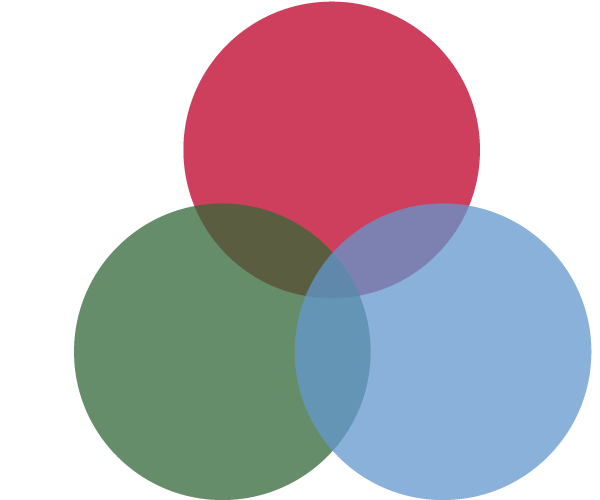

To be useful, a color proof must match the color, tonal range and visual appearance of the printing process. First, the colorants of the proofing system must simulate both the primary and secondary hues produced by the printing inks. Next, the proof must simulate the tone compression inherent in the printing process used. Finally, a roof must match the overall appearance of the printed sheet. Factors that affect overall appearance include the substrate, or paper stock, and gloss level.

A common pitfall is to judge a proof on how pleasing it is to the eye without considering how well it represents the printing process If a proof cannot be matched on press, the proof creates frustrations for the press operator and unrealistic expectations for the customer.